What is Sugarcane Bagasse ?

Vietnam is one of the countries which have the strongest strengths in the agricultural sector, with biomass sources from other agricultural by-products… Therefore, if it is not used rationally, it would easily cause a waste of resources. And more than that, the pollution is extremely serious if not handled properly. The resource that we want to introduce to you in this article is bagasse.

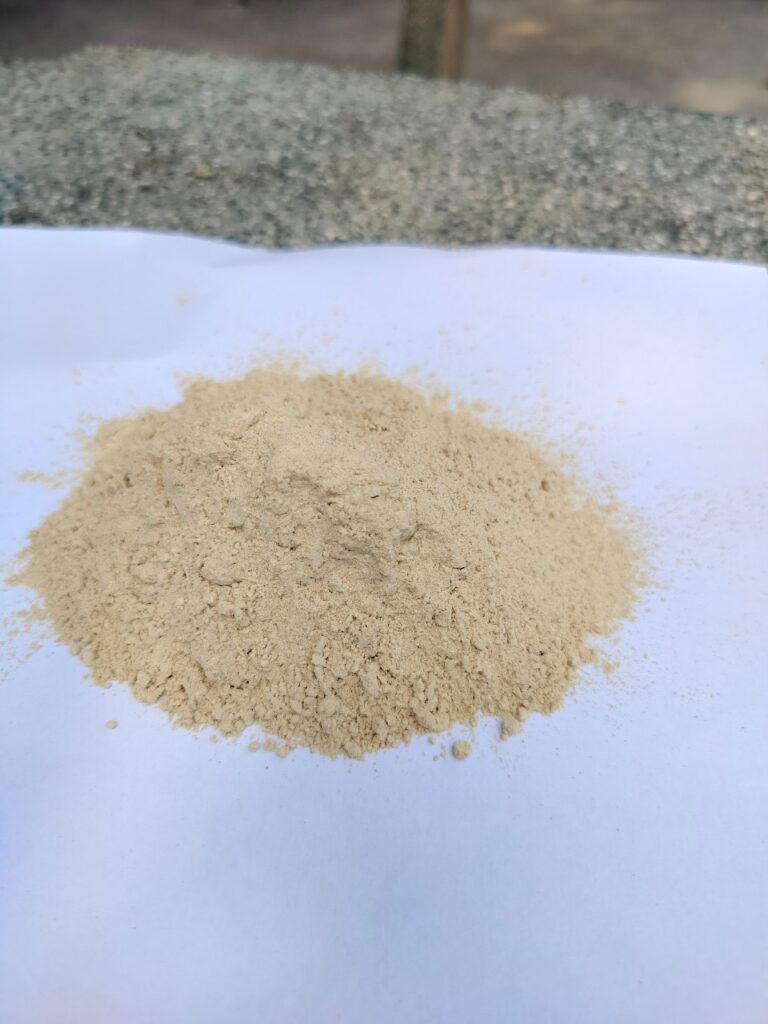

Sugarcane after being pressed for juice or produced, they come out the remaining fiber of the body called bagasse, also known as sugarcane carcass. The main ingredients are fibrous fibers (cellulose), juice and a relatively small amount of dissolved substances, mainly sugars. Sugarcane bagasse has the following characteristics:

– Physical characteristics: The bagasse is fibrous, insoluble in water as well as other solvents. It is ivory white, light green, or purple depending on the original characteristics of each type of sugarcane.

– Chemical characteristics: Bagasse has a chemical composition including the following substances: Cellulose, Hemicellulose, Lignin, and other soluble substances (ash, wax, protein…). These ingredients can vary depending on the sugarcane variety, soil conditions as well as the care process. When burned, bagasse produces substances such as CO2, SO2, N2, .. This process gives off a lot of heat. Therefore, it is used as a fuel for a number of industries.

Production, Storage and Properties

With bagasse being a by-product of sugarcane, the production quantity of bagasse in each country is in line with the quantity of sugarcane produced. The typical ratio is 3 tonnes of wet bagasse for every 10 tonnes of sugarcane crushed. This also means that the biggest producers of bagasse are Brazil and India as they are the largest sugarcane growing regions.

Once bagasse fibres are gathered from residual sugarcane, they are stored wet in order to remove any residual sugar which may impede further production. The bagasse is then blended with water until the compounds finally develop into a pulp which can then be further processed.

Bagasse is stored in different ways depending on its end use. In general, it is stored ahead of further processing. In electricity production for example, bagasse has to be kept in moist conditions with a mild exothermic process that results in drying the fibres gradually over time. In paper and pulp production however, bagasse has to be kept wet in order to aid the removal of ‘pith’ fibres. Pith fibres make up around 30-40% of bagasse and are derived from the core of the sugarcane plants, the properties of which hinder paper production.

Typically, dried bagasse is chemically made up of:

- 45-55% Cellulose

- 20-25% Hemicellulose

- 18-24% Lignin

- 1-4% Ash

- <1% Waxes