What is bagasse ?

Vietnam is one of the countries with strengths in the agriculture sector, with various biomass sources from agricultural by-products. Therefore, if these resources are not properly utilized, it can easily lead to wastage. Moreover, if not handled correctly, it can cause severe pollution. The resource that we want to introduce to you in this article is bagasse.

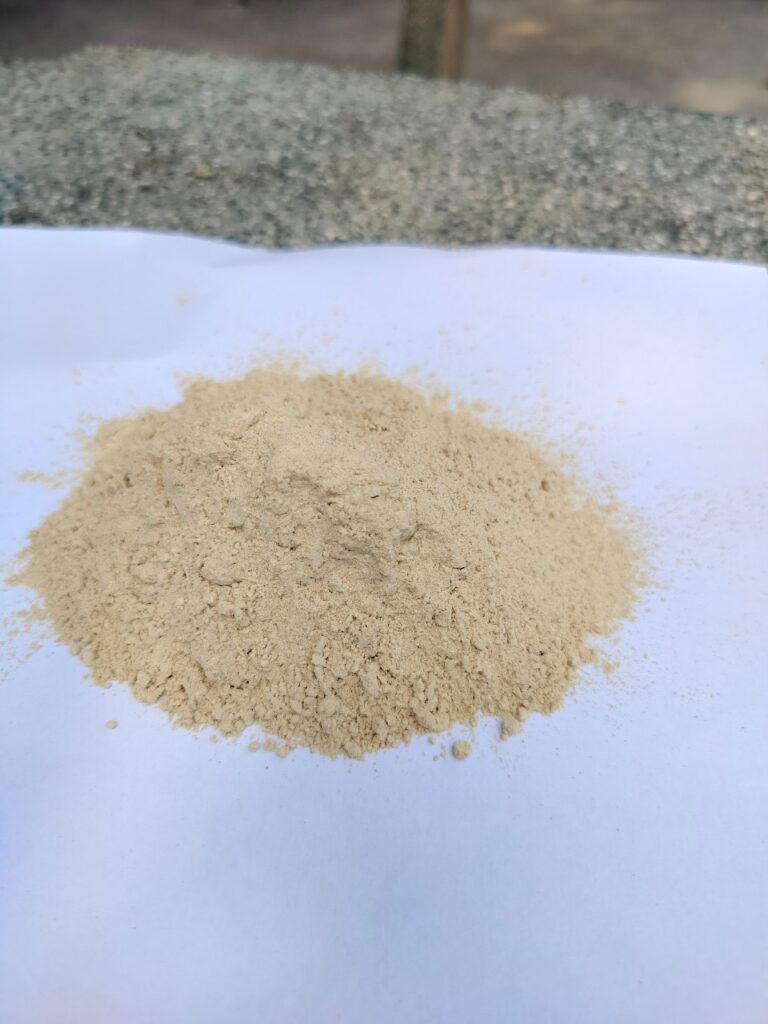

After sugarcane is pressed to extract juice or produce sugar, the remaining fiber of the stalk is called bagasse or sugarcane residue. Its main components include fiber (cellulose), water, and a relatively small amount of soluble substances, primarily sugar. Bagasse has the following characteristics:

• Physical characteristics: Bagasse is fibrous and insoluble in water and other solvents. It has an ivory, light green, or purple color depending on the initial characteristics of the sugarcane variety. The main components of bagasse are fiber, water, and a small amount of soluble substances.

• Chemical characteristics: Bagasse has the following chemical components: cellulose, hemicellulose, lignin, and other soluble substances (ash, wax, protein, etc.). These components can vary depending on the sugarcane variety, soil conditions, and cultivation processes. When burned, bagasse produces substances such as CO2, SO2, N2, and emits a significant amount of heat. Therefore, it is applied as a fuel in some industries.

Production, storage, and characteristics

As bagasse is a by-product of sugarcane, the amount of bagasse produced in each country corresponds to the amount of sugarcane produced. The typical ratio is 3 tons of wet bagasse for every 10 tons of pressed sugarcane. This also means that the largest producers of bagasse are Brazil and India, as they are the largest sugarcane-growing regions.

After collecting bagasse fibers from sugarcane debris, they are stored wet to remove any remaining sugar that could hinder the subsequent production process. Bagasse is then mixed with water until the final compounds develop into pulp, which can be further processed.

The storage methods for bagasse vary depending on the ultimate purpose of use. It is typically stored prior to further processing. For example, in electricity generation, bagasse needs to be kept in moist conditions with a slight exothermic process that gradually dries the fibers over time. However, in paper and pulp production, bagasse needs to be kept moist to help remove the “pith” fibers. Pith fibers make up about 30-40% of bagasse and are extracted from the central part of the sugarcane stalk, posing challenges to paper production.

Typically, dry bagasse has the following chemical composition:

• 45-55% cellulose

• 20-25% hemicellulose

• 18-24% lignin

• 1-4% ash

• <1% wax

Applications of Bagasse

Bagasse is used as a component in animal feed.

As mentioned earlier, bagasse is used as a substitute for wood in many tropical and subtropical countries for paper production, such as India, Argentina, and Colombia.

Bagasse produces a pulp with physical properties suitable for printing paper, newsprint, cardboard, particleboard, laminated wood, and even furniture and biodegradable plastics. It can also be used in the production of “furfural,” a colorless transparent liquid used in the synthesis of chemical products such as nylon and solvents.

Bagasse is commonly used as a fuel source for natural sugar mills. When burned in large quantities, bagasse generates enough heat to meet, or even exceed, the energy needs of a standard sugar mill. It can also be used as a co-fuel in cogeneration processes, where bagasse can be used to generate electricity, which can be sold to the power grid for consumption.

There is ongoing research on using bagasse as a renewable biofuel for power generation. It has the potential to become an environmentally friendly alternative to corn for bioethanol fuel. Due to its high cellulose content, bagasse can produce a large amount of ethanol from cellulose. Studies have demonstrated the feasibility of bagasse in ethanol production, although its compatibility with conventional engines still needs further investigation. Bagasse is also used for producing animal feed by combining it with molasses and enzymes. The ‘K-Much’ industry has patented a method to convert bagasse into animal feed, and this product is marketed in many countries such as Thailand, Japan, South Korea, and Australia.

Sustainability

Research is currently being conducted to establish bagasse as an alternative biofuel or power production method, similar to wind, solar, and wave energy. As mentioned in our previous articles on sugarcane, sugarcane is a fast-growing and renewable resource. Bagasse, as a by-product of sugar production, is also sustainable. While research on using bagasse for biofuel production is ongoing, it does not require cutting down trees, thus not impacting forests or additional cultivation areas. Bagasse is a sustainable and environmentally friendly alternative to traditional paper production, which uses wood and consumes less energy in its production process.

Bagasse-based plastic and hardware products are completely biodegradable and can decompose in as little as four weeks under the right conditions. Many restaurants, in an effort to be more environmentally friendly, have replaced their plastic and Styrofoam packaging with bagasse products, and even some of their tableware is made from bagasse. In fact, bagasse is dominating the takeaway industry because they clearly have high demand for single-use items. Bagasse allows these industries to participate in sustainable practices with excellent solutions replacing disposable plates, bowls, and paper towels. Bagasse is not only an efficient sustainable resource but also a reliable resource.